Washable, weavable, rechargeable thermally drawn fiber battery

This submarine drone is powered by a 20-meter-long fiber battery that is wrapped on its surface. Image: Courtesy of the researchers

The fiber battery continues to power an LED even after partial cutting indicating that the fiber battery system is free from electrolyte loss and from short-circuiting. Image: Courtesy of the researchers

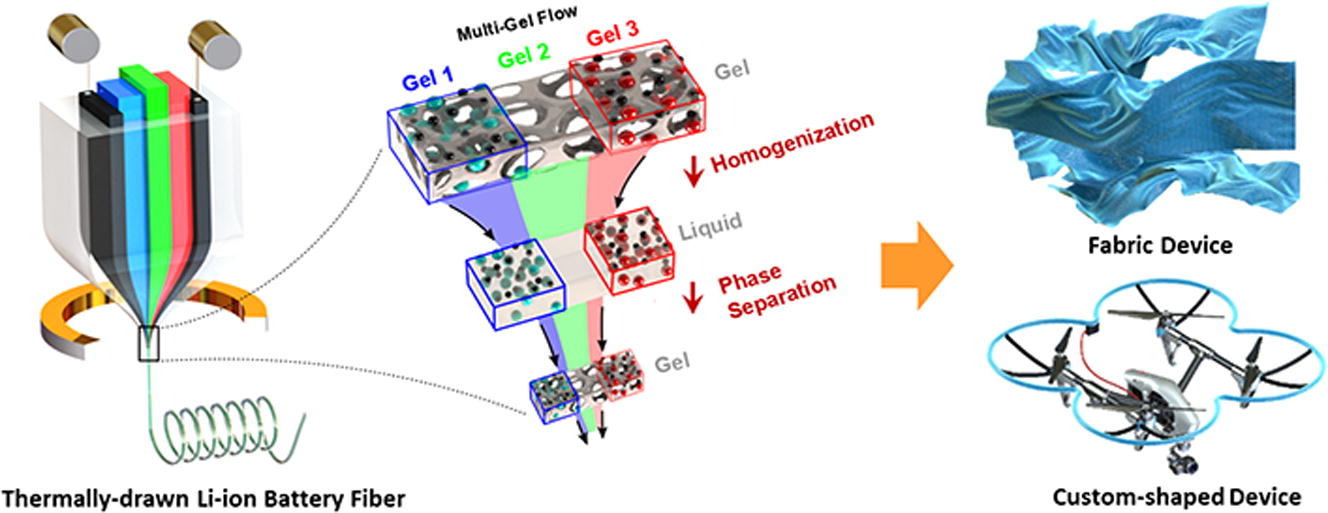

Thermal fiber battery drawing including multiple gels and its expansion into 2D and 3D flexible multidimensional electronics. The thermally drawn fiber battery consists of lithium-iron-phosphate (LFP) gel for the cathode, lithium titanate (LTO) gel for the anode, electrolyte gel, cyclic olefin copolymer (COC) cladding, and metal wires embedded in carbon-loaded polyethylene (CPE). The PVDF and EC:PC solvent mixture in LFP, LTO, and electrolyte gels are homogenized at the elevated temperature (in the furnace) and then phase-separated at room temperature (outside the furnace) forming interconnected pore structures with minimal gaps between cathode, anode, and electrolyte. The fiber battery can be integrated with electronic components to form 1D, 2D, and 3D electronic devices. Image: T. Khudiyev, B. Grena,et al. Thermally drawn rechargeable battery fiber enables pervasive power, Materials Today, Volume 52, 2022, Pages 80-89.