Low-hysteresis shape-memory ceramics

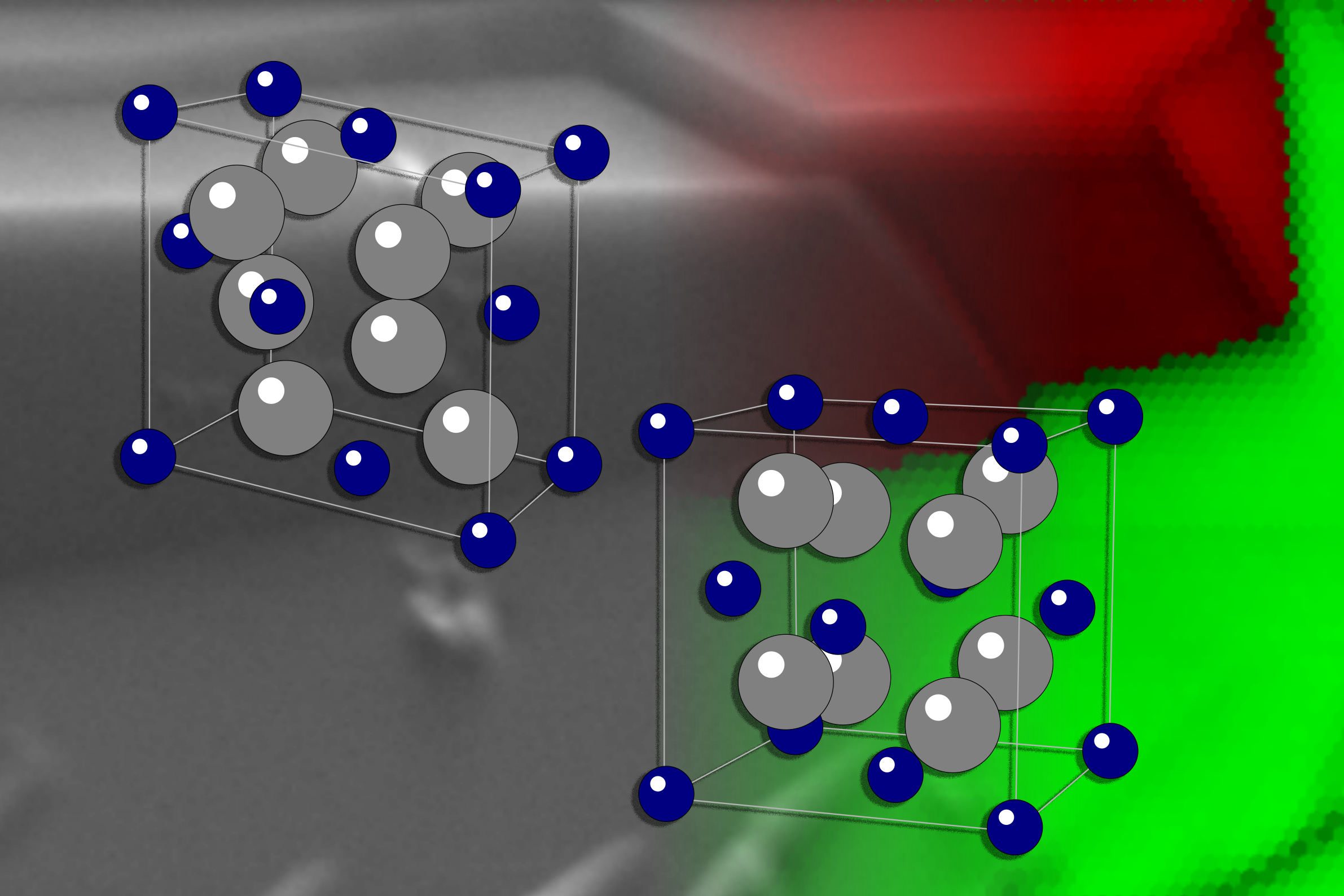

Diagrams show the two different ways that the atomic structure of the shape-memory material, zirconia ceramic, can be configured. An external trigger such as a temperature change can shift the configuration from one shape to the other, changing its dimensions and allowing it to exert pressure or do other work. The background is an electron microscope image of the material, with the two colors indicating the two different configurations. Image: Edward Pang