Long Nanofiber Reinforcement of Bulk Ceramics

Emerging military applications including hypersonics require the development of lightweight ceramic composites with enhanced thermal stability and shock resistance, necessitating ceramics with high strength and fracture toughness at elevated temperatures. Bulk ceramics with enhanced fracture toughness and ductile failure behavior have been recently engineered via nanoporosity and nanofibers, but with limitations in processing and scale. In this project, the Schuh and Wardle research groups will study a new platform for creating tough and strong long-nanofiber-reinforced bulk ceramics at extreme volume fractions and nanofiber lengths far beyond what is currently possible by combining new findings across three investigations: the synthesis of bulk-scale arrays of high-quality crystalline and transparent aligned boron nitride nanotubes, a new bulk nanocomposite laminating process developed at MIT, and the model-guided synthesis of high-temperature carbon-matrix nanocomposites reinforced with aligned carbon nanotubes.

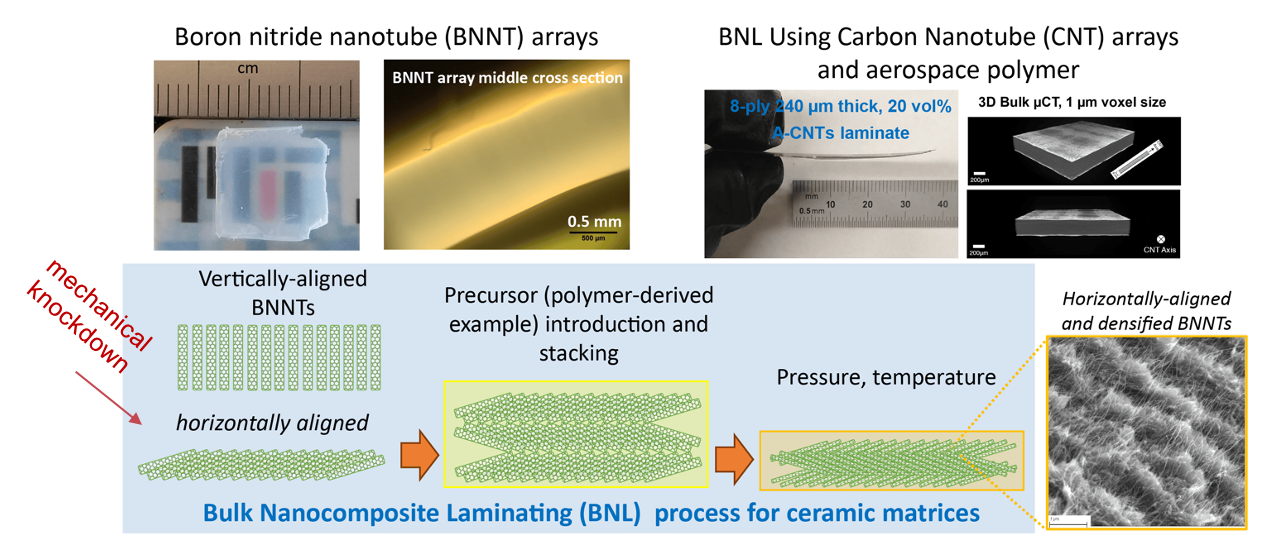

Polymer example of proposed Bulk Nanocomposite Laminating (BNL) process for ceramic-matrix composites with thermally stable crystalline boron nitride nanotube (BNNT) arrays.